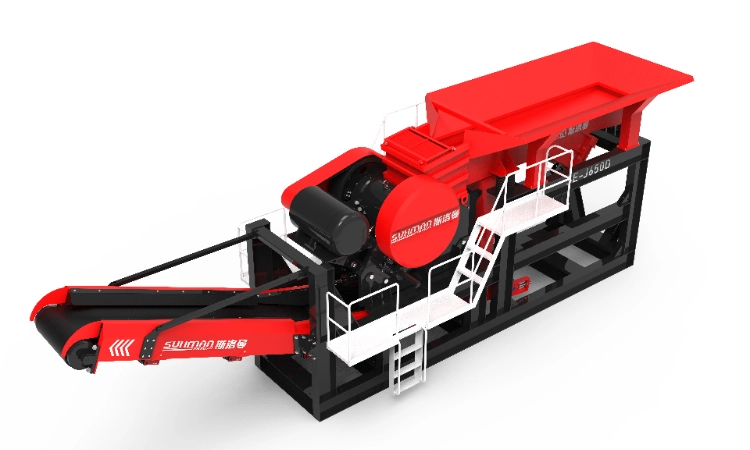

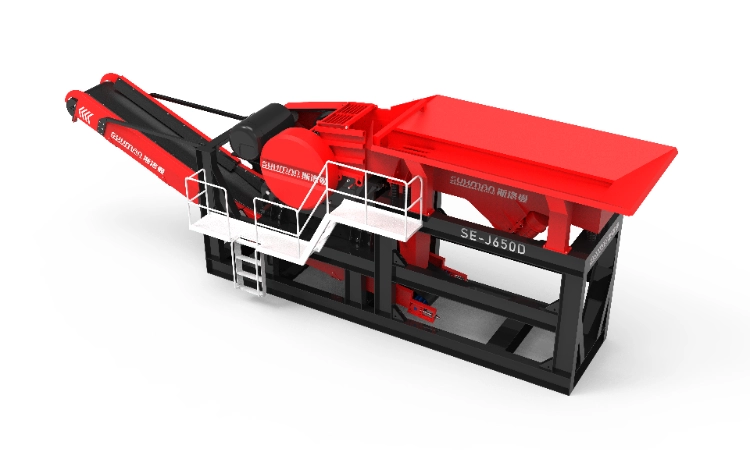

The modular jaw crusher is durable, using forged heavy-duty eccentric shafts, high-quality heavy-duty self-aligning roller bearings, etc., ensures the impact resistance and high stability of the movable jaw assembly, while increasing throughput and material crushing frequency, and increasing production.

Jaw crusher has strong adaptability, it has low requirements for raw material size, strong adaptability, large feed inlet, can handle larger raw materials, and can also adapt to different material types and particle sizes.

Working Principle

Application

This is a small jaw crusher produced to meet the crushing production demand of customers who are not particularly high. Used for preliminary crushing of large ore blocks extracted, breaking them into smaller particle sizes for subsequent transportation and further processing. Jaw crusher is an important front-end equipment.

Video Presentation

Product Parameter

| Serial number | Project | Description | SE-J650D |

| 1 | Feeding equipment | Hopper volume(m³) | 4 |

| 2 | Feed height(mm) | 3500 | |

| 3 | Maximum feed size(mm) | 500 | |

| 4 | Size of feeder (length x width)(mm) | 3600×700 | |

| 5 | Feed capacity (t/h) | 50-130 | |

| 6 | Power of Feeder | 3kw×2 | |

| 7 | Jaw Crusher | Models | 57 |

| 8 | Maximum feed particle size (mm) | 500 | |

| 9 | Inlet size (length x width)(mm) | 500×700 | |

| 10 | Processing capacity(t/h) | 50-130 | |

| 11 | Discharge particle size range(mm) | 0-100 | |

| 12 | Power(kw) | 75 | |

| 13 | Weight(t) | 10.1 | |

| 14 | Main belt conveyor | Width/length (mm) | 800×15100 |

| 15 | Discharge height(mm) | 2100 | |

| 16 | Power(kw) | 11 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 |

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)

.png)