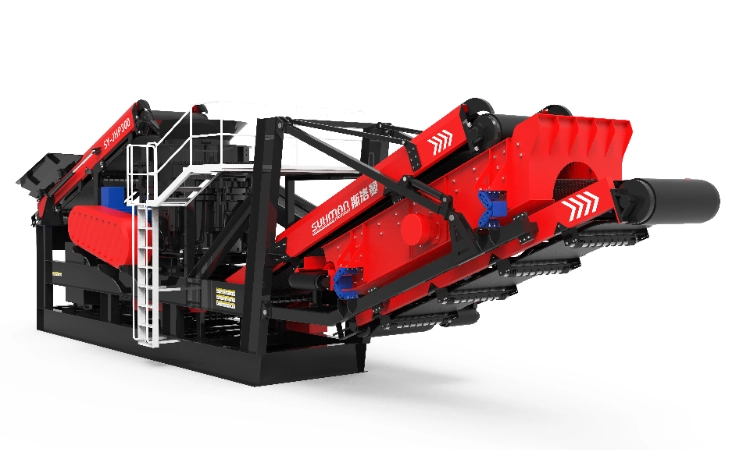

The tracked mobile impact plant for sand making has shown outstanding performance in energy conservation and environmental protection. It adopts advanced energy-saving technologies, such as load sensitive variable displacement pumps and electromagnetic proportional multi way valves, to ensure that the hydraulic system is efficient, powerful, and energy-saving. During the homework process, impact crusher can effectively reduce energy consumption and lower production costs. At the same time, mobile impact plant also has good environmental performance, effectively reducing dust emissions and noise pollution through multiple protective measures such as dust prevention, waterproofing, and noise reduction. For example, in urban construction projects with high environmental requirements, this sand making machine can meet production needs while minimizing the impact on the surrounding environment.

Working Principle

Application

This machine is used for the production of various materials, including:

Metals and Non-Metals: Ores, cement, refractory materials, and glass raw materials.

Building Aggregates: Artificial sand from river pebbles, mountain stones (such as limestone, granite, basalt, diabase, and andesite), and ore tailings.

Pavement Materials: Highway pavement materials, cushion materials, and aggregates for asphalt and cement concrete.

Metallurgical Slag: Fine and coarse grinding operations of various metallurgical slag, particularly effective for medium-hard, extra-hard, and abrasive materials like silicon carbide, diamond sand, sintered aluminum vanadium soil, and magnesia sand.

The machine also pairs well with hydraulic protection systems for jaw fractures, allowing it to handle various metallurgical slag effectively. It is suitable for both construction sand and road construction sand and gravel.

Video Presentation

Product Parameter

| Serial number | Project | Description | SC-85D |

| 1 | Feeding equipment | Hopper volume(m³) | 3 |

| 2 | Maximum feed size(mm) | 50 | |

| 3 | Feed capacity (t/h) | 150-350 | |

| 4 | Power of Feeder | 7.5(kw)×2 | |

| 5 | Impact Crusher For | Models | 85D |

| 6 | Maximum feed particle size (mm) | 50 | |

| 7 | Inlet size (length x width)(mm) | 1540×1000 | |

| 8 | Processing capacity(t/h) | 250 | |

| 9 | Power(kw) | 220 | |

| 10 | Weight(t) | 18 | |

| 11 | Main belt conveyor | Width/length (mm) | 1200×19100 |

| 12 | Discharge height(mm) | 3200 | |

| 13 | Power(kw) | 15 | |

| 14 | Track system | Country of origin | England |

| 15 | Brand | Strickland | |

| 16 | Specification length x width(mm) | 4500×500 | |

| 17 | Maximum inclination of walking (°) | 30 | |

| 18 | Walking speed(km/h) | 0.8-1.5 | |

| 19 | Power System (for single walking) | Models | QSB3.9-G3 |

| 20 | Fuel consumption (L/h) | 3.9 | |

| 21 | Power(kw) | 79 | |

| 22 | Tank volume(L) | 200 | |

| 23 | Emission standards | National III | |

| 24 | Power System -LRB-both oil and electricity) | Models | QSZ13-G11 |

| 25 | Brand | CUMMINS | |

| 26 | Fuel consumption (L/h) | ||

| 27 | Power(kw) | 512 | |

| 28 | Tank volume(L) | 600 | |

| 29 | Emission standards | National III | |

| 30 | Accessories brand | Control System (electrical) | Chuan Ken |

| 31 | Walking system | Strickland | |

| 32 | Conveyor belt | Qingdao Global | |

| 33 | hydraulic machinery | Bomke | |

| 34 | The engine | CUMMINS | |

| 35 | Steel | Models | Q355B(Materials used for warships) |

| 36 |

The whole machine |

Weight(t) | 37 |

| 37 | Shipping dimensions(mm) | 15000×3200×3800 | |

| 38 | Working size(mm) | 14400×3200×4300 |

Tags

- heavy-duty machinery

- high crushing ratio mobile crusher

- mobile aggregate crusher

- mobile asphalt crusher

- mobile concrete crusher

- mobile quarry crusher

- tracked mobile crusher

.png)

Next Product:Mobile Cone Crusher Plus with Greater Crushing Capacity

Previous Product:Crawler Type Mobile Impact Crusher Produced in China

.png)

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)