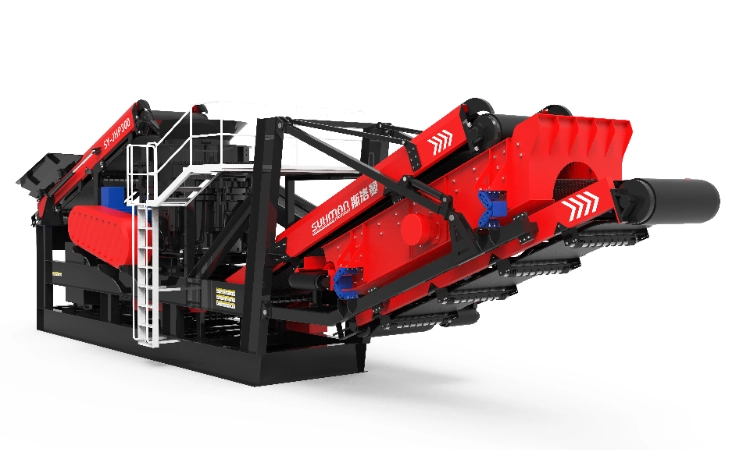

Jaw crusher plays an important role in many industrial fields and is one of the key equipment for material crushing and processing. The mobility performance of the tracked mobile jaw crusher is excellent. Its fully hydraulic-driven tracked vehicle chassis provides stronger grip and allows for flexible movement in various road conditions. Without the need for complicated transportation and installation processes, the equipment can be directly transported to the work site and quickly put into operation. For example, in road construction projects, it can follow the construction progress and transfer at any time, greatly improving work efficiency. Moreover, it has a small turning radius and can easily turn in narrow spaces without being limited by the site.

Working Principle

Application

Crawler-type mobile jaw crushers are widely used in mining, stone mining, highway (railway) and bridge construction, recycling, and reprocessing of construction waste, and many other fields. They can be used to crush various materials such as river pebbles, mountain rocks (such as limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips, etc. Optimization design can improve the technical performance of crushers, achieving high productivity and uniform particle size of finished materials.

Video Presentation

Product Parameter

| Serial number | Project | Description | SE-1060 |

| 1 | Feeding equipment |

Hopper volume(m³) | 5 |

| 2 | Feed height(mm) | 3800 | |

| 3 | Maximum feed size(mm) | 700 | |

| 4 | Size of feeder (length x width)(mm) | 3350×1000 | |

| 5 | Feed capacity (t/h) | 150-400 | |

| 6 | Power of Feeder | 3kw×2 | |

| 7 | Jaw Crusher | Models | 1060 |

| 8 | Maximum feed particle size (mm) | 700 | |

| 9 | Inlet size (length x width)(mm) | 700×1060 | |

| 10 | Processing capacity(t/h) | 150-400 | |

| 11 | Discharge particle size range(mm) | 0-300 | |

| 12 | Power(kw) | 110 | |

| 13 | Weight(t) | 14.35 | |

| 14 | Main belt conveyor | Width/length (mm) | 1200×22450 |

| 15 | Discharge height(mm) | 2950 | |

| 16 | Power(kw) | 15 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 | |

| 22 | Side belt conveyor (Optional) |

Width/length (mm) | / |

| 23 | Discharge height(mm) | / | |

| 24 | Power(kw) | / | |

| 25 | Track system | Country of origin | England |

| 26 | Brand | Strickland | |

| 27 | Specification length x width(mm) | 4160×500 | |

| 28 | Maximum inclination of walking (°) | 30 | |

| 29 | Walking speed(km/h) | 0.8-1.5 | |

| 30 | Power System (for single walking) | Models | QSB3.9-G3 |

| 31 | Fuel consumption (L/h) | 3.9 | |

| 32 | Power(kw) | 79 | |

| 33 | Tank volume(L) | 200 | |

| 34 | Emission standards | National III | |

| 35 | Power System -LRB-both oil and electricity) | Models | 6TAA8.9-G3(CUMMINS) |

| 36 | Fuel consumption (L/h) | ||

| 37 | Power(kw) | 255 | |

| 38 | Tank volume(L) | 600 | |

| 39 | Emission standards | National III | |

| 40 | Accessories brand | Control System (electrical) | Chuan Ken |

| 41 | Walking system | Strickland | |

| 42 | Conveyor belt | Qingdao Global | |

| 43 | Hydraulic machinery | Bomke | |

| 44 | The engine | CUMMINS | |

| 45 | Steel | Models | Q355B(Materials used for warships) |

| 46 |

The whole machine |

Weight(t) | 41 |

| 47 | Shipping dimensions(mm) | 14850×3100×3800 | |

| 48 | Working size(mm) | 14850×3100×3800 |

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)

.png)