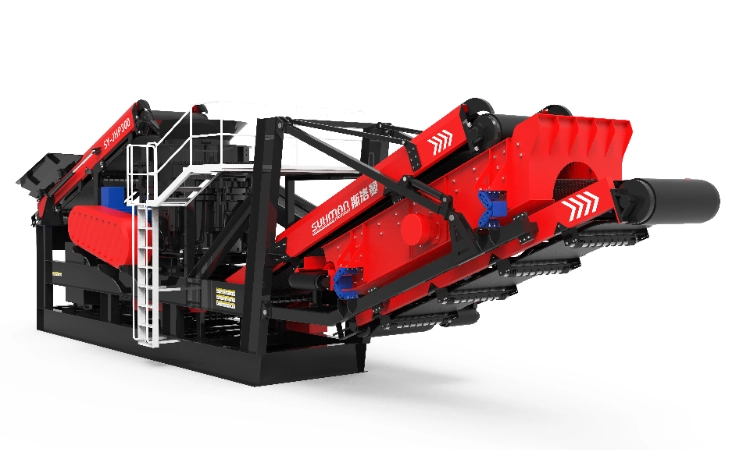

The tracked mobile jaw crusher has strong processing capacity. It can handle various types and sizes of materials, with large feed particle size and wide discharge range. For example, in mining ore crushing, hundreds or even thousands of tons of ore can be processed per hour. Its high-yield and high-efficiency characteristics enable large-scale crushing operations to be completed quickly, meeting the large demand for materials in various engineering projects.

Mobile jaw crusher plant has significant integration advantages. It integrates feeding, conveying, crushing and other processes into a compact whole. This integrated design eliminates tedious component installation and infrastructure construction, reducing labor and material consumption. In practical applications, such as construction waste recycling, integrated equipment can quickly crush and transport waste, improve operational efficiency, reduce operational steps, and lower costs.

Working Principle

Application

Crawler type mobile jaw crushers can process materials of various hardness, from soft materials to rocks with higher hardness, such as river pebbles and mountain rocks (such as limestone, granite, basalt, diabase, andesite, etc.), which can be effectively crushed. They are widely used in various fields such as mining tailings, chip mining, stone mining, highway (railway) and bridge construction, and recycling and reprocessing of construction waste.

Video Presentation

Product Parameter

| Serial number | Project | Description | SE-1160 |

| 1 | Feeding equipment | Hopper volume(m³) | 6 |

| 2 | Feed height(mm) | 4020 | |

| 3 | Maximum feed size(mm) | 800 | |

| 4 | Size of feeder (length x width)(mm) | 4000×1120 | |

| 5 | Feed capacity (t/h) | 170-450 | |

| 6 | Power of Feeder | 3.7kw×2 | |

| 7 | Jaw Crusher | Models | 1160 |

| 8 | Maximum feed particle size (mm) | 800 | |

| 9 | Inlet size (length x width)(mm) | 800×1160 | |

| 10 | Processing capacity(t/h) | 170-450 | |

| 11 | Discharge particle size range(mm) | 0-300 | |

| 12 | Power(kw) | 135 | |

| 13 | Weight(t) | 18.6 | |

| 14 | Main belt conveyor | Width/length (mm) | 1200×23700 |

| 15 | Discharge height(mm) | 3150 | |

| 16 | Power(kw) | 15 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 | |

| 22 | Side belt conveyor (Optional) |

Width/length (mm) | 550×10300 |

| 23 | Discharge height(mm) | 2760 | |

| 24 | Power(kw) | 3kw | |

| 25 | Track system | Country of origin | England |

| 26 | Brand | Strickland | |

| 27 | Specification length x width(mm) | 4500×500 | |

| 28 | Maximum inclination of walking (°) | 30 | |

| 29 | Walking speed(km/h) | 0.8-1.5 | |

| 30 | Power System (for single walking) | Models | QSB3.9-G3 |

| 31 | Fuel consumption (L/h) | 3.9 | |

| 32 | Power(kw) | 79 | |

| 33 | Tank volume(L) | 200 | |

| 34 | Emission standards | National III | |

| 35 | Power System -LRB-both oil and electricity) | Models | 6TAA8.9-G3(CUMMINS) |

| 36 | Fuel consumption (L/h) | ||

| 37 | Power(kw) | 255 | |

| 38 | Tank volume(L) | 600 | |

| 39 | Emission standards | National III | |

| 40 | Accessories brand | Control System (electrical) | Chuan Ken |

| 41 | Walking system | Strickland | |

| 42 | Conveyor belt | Qingdao Global | |

| 43 | hydraulic machinery | PERMCO | |

| 44 | The engine | CUMMINS | |

| 45 | Steel | Models | Q355B(Materials used for warships) |

| 46 |

The whole machine |

Weight(t) | 48 |

| 47 | Shipping dimensions(mm) | 14850×3400×4020 | |

| 48 | Working size(mm) | 14850×3400×4020 |

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)

.png)

.png)