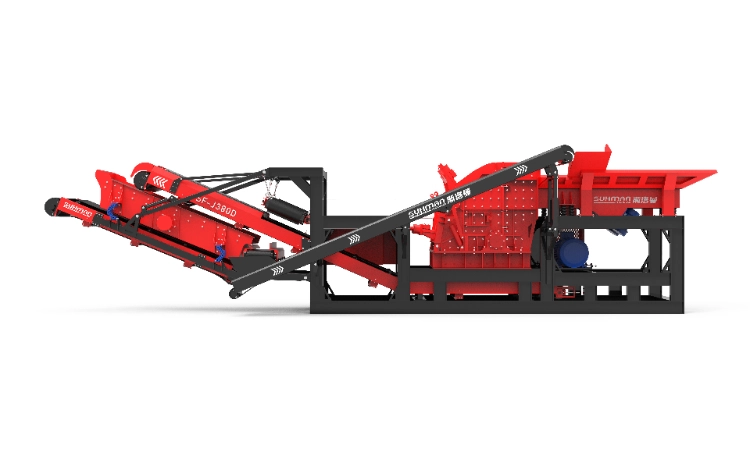

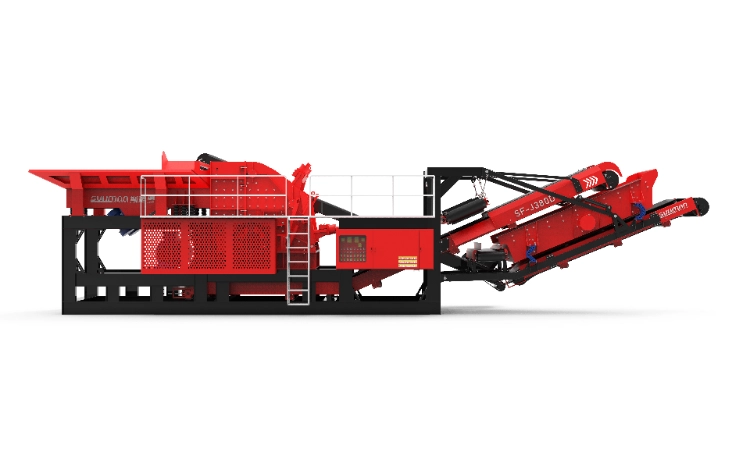

The plate hammer of the modular impact crusher is fixed to the rotor using a mechanical clamping structure. The rotor, having high momentum, is capable of crushing materials with high hardness while consuming less energy. Wear on its vulnerable parts is relatively minimal, and the bottom grinding rod is easy to replace. Spare parts are also easy to replace, which reduces maintenance costs. The discharge particle size can be adjusted in various ways, such as by changing the rotor speed or the clearance between the impact plate and the grinding chamber, offering a wide range of adjustment options.

Working Principle

Application

The impact crusher is highly adaptable to various materials. It can crush materials such as construction waste, bluestone, slag, quartz sand, limestone, and quartz stone. Whether used in mining, construction waste recycling, or road construction, it performs effectively in crushing applications.

Video Presentation

Product Parameter

| Serial number | Project | Description | SF-J380D |

| 1 | Feeding equipment | Hopper volume(m³) | 5 |

| 2 | Feed height(mm) | 3700 | |

| 3 | Maximum feed size(mm) | 700 | |

| 4 | Size of feeder (length x width)(mm) | 3500×1300 | |

| 5 | Feed capacity (t/h) | 150-350 | |

| 6 | Power of Feeder | 3(kw)×2 | |

| 7 | Impact Crusher | Models | 380D |

| 8 | Maximum feed particle size (mm) | 700 | |

| 9 | Inlet size (length x width)(mm) | 1380×1000 | |

| 10 | Processing capacity(t/h) | 150-350 | |

| 11 | Power(kw) | 250 | |

| 12 | Weight(t) | 16 | |

| 13 | Vibrating screen | Screen size (length x width)(mm) | 5000×1500 |

| 14 | Maximum feeding granularity(mm) | 100 | |

| 15 | Processing capacity(t/h) | 150-450 | |

| 16 | Power(kw) | 3.7(kw)×2 | |

| 17 | The number of screen layer (layer) | 1 | |

| 18 | Sift down the belt | Width/length (mm) | 1000×11500 |

| 19 | Discharge height(mm) | 2600 | |

| 20 | Power(kw) | 7.5 | |

| 21 | Main belt conveyor (top of the screen) | Width/length (mm) | 1200×22050 |

| 22 | Discharge height(mm) | 3400 | |

| 23 | Power(kw) | 15 | |

| 24 | Iron remover | Models | RCYD-12 |

| 25 | Power(kw) | 3 | |

| 26 | Processing capacity(t/h) | 0-20 | |

| 27 | Size(mm) | 2100*1450*420 | |

| 28 | Weight(kg) | 900 | |

| 29 | Side belt conveyor | Width/length (mm) | / |

| 30 | Discharge height(mm) | / | |

| 31 | Power(kw) | / | |

| 32 | Transition Belt Machine | Width/length (mm) | 500×4400 |

| 33 | Discharge height(mm) | 1300 | |

| 34 | Power(kw) | 3 | |

| 35 | Return material belt machine | Width/length (mm) | 500×15700 |

| 36 | Discharge height(mm) | 4000 | |

| 37 | Power(kw) | 5.5 |

.png)

.png)

.png) +8613655550150

+8613655550150

.png) Inquiry Now

Inquiry Now

.png)

.png)

.png)

.png)

.png)

.png)