Мобильная щековая дробилка: оптимальное решение для мобильного дробления и высокопроизводительных дробильных операций

Release time: 2025-03-06

Introduction to Mobile Jaw Crushers

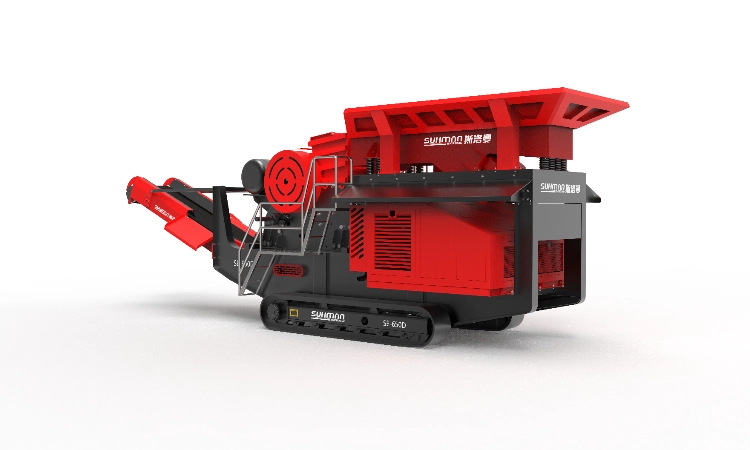

In the fast-evolving construction and mining sectors, the need for portable, powerful, and flexible crushing solutions is more critical than ever. Among the top contenders, the mobile jaw crusher stands out as an essential piece of equipment due to its mobility, efficiency, and high-performance capabilities. This portable crusher is designed to provide a compact crushing solution that delivers high-output results in both primary and secondary crushing stages.

Portable mobile jaw crushers are increasingly used in a variety of industries, including construction, mining, and recycling, thanks to their ability to work directly on-site and handle tough materials like rock, concrete, and even recycled asphalt. This article will delve into the features, applications, and benefits of mobile jaw crushers, helping you understand why they are becoming a go-to choice for modern crushing operations.

Что такое мобильная щековая дробилка?

A mobile jaw crusher is a type of portable crusher designed to crush materials such as rock, stone, ore, and concrete. Unlike traditional stationary crushers, a mobile jaw crusher is mounted on a crawler chassis or wheeled platform, allowing it to be easily transported and relocated for various job sites. The compact design and powerful crushing performance make it ideal for industries that require flexibility and efficiency in material processing.

A mobile jaw crusher typically consists of several components, including a vibrating feeder, a jaw crusher, a belt conveyor, and sometimes, an electric generator or diesel engine for energy supply. With the ability to move directly to the material, this mobile crushing unit eliminates the need for transporting materials to a fixed plant.

Key Features of Mobile Jaw Crushers

1. Portability and Mobility:

The main advantage of a mobile jaw crusher is its portability. These мобильные дробильные установки can be easily transported from one site to another, ensuring that materials can be processed directly at the crushing site, minimizing transportation costs and reducing project time.

2. High Crushing Efficiency:

Mobile jaw crushers are designed to deliver high crushing capacity and performance in a compact, mobile format. The high-output crushing allows for fast and efficient material processing, even in the toughest environments.

3. Versatility and Multi-Functional Design:

Mobile jaw crushers are incredibly versatile, handling a wide range of materials. They are ideal for primary crushing of various hard and abrasive materials such as granite, basalt, limestone, and concrete, as well as secondary crushing when paired with other crushers.

4. Eco-Friendly Features:

The latest mobile jaw crushers are engineered with energy efficiency in mind. With low emissions, fuel-efficient engines, and reduced noise, these crushers are better for the environment while maintaining optimal performance.

5. Advanced Technology and Automation:

Modern mobile jaw crushers come equipped with automated control systems, remote monitoring, and user-friendly interfaces. These advancements make it easier to monitor operational performance, track production data, and optimize the machine for maximum efficiency.

Applications of Mobile Jaw Crushers

Mobile jaw crushers are used in a wide variety of industries, each benefiting from the flexibility and efficiency of this мобильное дробильное оборудование:

1. Mining Industry:

In the mining industry, mobile jaw crushers are indispensable for ore crushing and rock processing. These crushers are perfect for hard rock crushing at mining sites, reducing the need for transporting materials to distant stationary plants. Whether you’re crushing gold ore, copper ore, or coal, the mobile jaw crusher is a vital tool for mineral extraction.

2. Construction and Demolition:

For construction projects and demolition work, mobile jaw crushers play a key role in crushing concrete, bricks, and asphalt. Their ability to process material directly on-site reduces transportation costs and waste disposal expenses. Crushing concrete, for example, can also produce recycled aggregates, which can be reused in new construction projects, making the process environmentally friendly.

3. Recycling Industry:

Mobile jaw crushers are widely used in recycling to crush scrap metal, concrete, and glass. These crushers are highly efficient for processing recycled materials, enabling on-site material recycling that reduces waste and contributes to sustainable practices.

4. Aggregate Production:

For businesses involved in aggregate production, mobile jaw crushers provide a cost-effective solution. Whether it’s for sand, gravel, or crushed stone production, these mobile crushers can handle large quantities of material, reducing the need for multiple machines and ensuring higher production rates.

Benefits of Mobile Jaw Crushers

1. Cost Savings:

The mobile jaw crusher provides significant cost savings due to its portability. Instead of transporting material to a stationary crusher, the mobile unit comes directly to the material, saving money on transport and setup costs. This reduces the overall operating expenses of any project.

2. Improved Productivity:

With high crushing rates and the ability to operate continuously, mobile jaw crushers are highly productive. They can process large volumes of material with minimal downtime, increasing the efficiency of your operation and ensuring that your project stays on schedule.

3. Minimal Environmental Impact:

Mobile jaw crushers are designed with eco-friendly features such as low fuel consumption, reduced emissions, and noise reduction technology. This helps companies meet environmental standards while reducing the carbon footprint of their operations.

4. Enhanced Safety Features:

Safety is a priority with modern mobile jaw crushers. Many units are equipped with safety guards, emergency stop systems, and remote control operations to protect workers and minimize operational risks.

How to Choose the Right Mobile Jaw Crusher

Selecting the best mobile jaw crusher for your project depends on several factors:

1. Material Type and Size:

Consider the type of materials you will be crushing. The crushing capacity and jaw opening size should match the material size and type. For instance, hard rocks may require a more powerful machine with a larger jaw opening.

2. Mobility Requirements:

If your project requires frequent relocation, choose a mobile jaw crusher that is easy to transport. Look for models with a compact design and fast setup times.

3. Production Capacity:

Evaluate the production capacity you need to meet your project deadlines. Higher capacity crushers are ideal for large-scale operations, while smaller crushers may suffice for specialized tasks.

4. Maintenance and Support:

Choose a manufacturer that offers excellent customer support and ensures easy access to spare parts. Routine maintenance is crucial for maintaining the crusher’s longevity and performance.

Заключение

The mobile jaw crusher is an indispensable piece of crushing equipment, offering unmatched portability, versatility, and high-performance crushing for industries like construction, mining, and recycling. With the ability to move directly to the material source, mobile jaw crushers help businesses reduce transportation costs, improve productivity, and minimize their environmental impact. By understanding the features, benefits, and applications of these crushers, you can make an informed decision to optimize your operations.

.png)

.png)

/>

/> />

/>