Working Principle

SF-580D-S Mobile Integrated Crushing and Screening Machine is a fully integrated crawler-type mobile unit that combines both crushing and screening functions in a single, compact system. It is designed to efficiently process construction waste and natural stone on-site, reducing the need for additional equipment and maximizing operational efficiency.

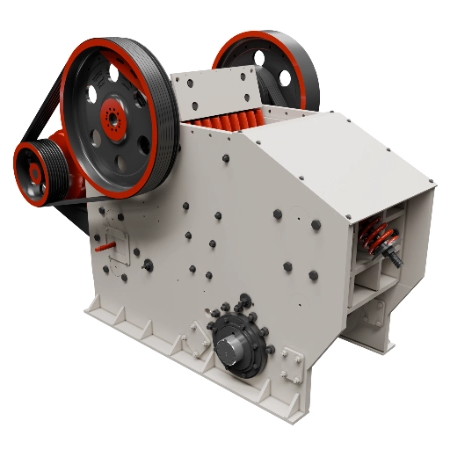

At the core of the unit is a heavy-duty three-chamber impact crusher. This powerful rotor system applies strong impact force to break down medium to hard materials, while a hydraulic adjustment system allows precise control of the final discharge size. An integrated pre-screening system located before the crusher removes fines and unwanted impurities, improving overall crushing efficiency and reducing wear on the crusher components.

After initial crushing, materials are transferred directly to a high-capacity dual-deck vibrating screen. This onboard screening system sorts the material into multiple end-product sizes. Oversized pieces are automatically returned to the crusher for further processing, forming a closed-loop crushing cycle.

The machine is equipped with a smart hydraulic control system for easy operation, including start/stop sequences and remote diagnostics. It supports diesel power or optional diesel-electric hybrid drive, allowing energy-efficient operation in a wide range of working environments. The durable crawler chassis ensures high mobility and stability, even on rough or uneven terrain.

Application

SF-580D-S Mobile Integrated Crushing and Screening Machine is ideal for operations requiring high productivity, multi-grade material output, and compact deployment. It is particularly suitable for the following applications:

-

Urban Construction Waste Recycling

The unit is well-suited for on-site crushing and screening of mixed demolition waste at construction or redevelopment projects. It produces reusable aggregate directly at the source, minimizing transport and handling costs. -

Large-Scale Infrastructure Demolition

Whether removing highways, bridges, or industrial facilities, the SF-580D-S provides fast setup and continuous operation, helping contractors meet demanding project schedules. -

Aggregate Production at Quarries or Supply Sites

The machine processes hard rock such as granite or limestone into multiple aggregate sizes suitable for commercial use or concrete production. -

Remote or Temporary Job Sites

For projects in remote areas or with short construction cycles, the SF-580D-S offers a flexible, all-in-one solution that requires no foundation setup and ensures quick production startup.

By integrating crushing and screening in one compact unit, the SF-580D-S significantly reduces footprint and setup complexity while improving overall efficiency and output quality. Optional configurations such as an overband magnet for metal separation, dust suppression systems, and remote control operation further enhance performance, safety, and environmental compliance.

Product Parameter

| Project | Name | SF-580D-S-DP |

| Feed section | Feeding capacity (t/h) | 300 |

| Hopper volume (m³) | 6 | |

| Power (kw) | 4.5×2 | |

| Feeder size (length x width) (mm) | 3950×1460 | |

| Feeding height (mm) | 4000 | |

| Crusher | Crusher model | 1315 |

| Feed inlet size (length x width) (mm) | 1540×1100 | |

| Maximum feed particle size (mm) | <700 | |

| Adjustment range of discharge port (mm) | 300-500\0-150 | |

| Crusher weight (t) | 23 | |

| Crusher power (kw) | 315 | |

| Main belt | Length x Width (mm) | 11500×1600 |

| Unloading height (mm) | 3250 | |

| Power (kw) | 9.5×2 | |

| Belt for finished materials | Length x Width (mm) | 5800×1350 |

| Unloading height (mm) | 2580 | |

| Power (kw) | 7.2×2 | |

| Return material hanging sieve | Length x Width (mm) | 5600×2160 |

| Power (kw) | 3.7×2 | |

| Number of sieve layers (layers) | 2 | |

| Screen size (mm) | 4600×1540 | |

| Transition belt | Length x Width (mm) | 1750×770 |

| Power (kw) | 3 | |

| Side conveyor belt | Length x Width (mm) | 6500×970 |

| Power (kw) | 5.5 | |

| Return conveyer belt | Length x Width (mm) | 7200×970 |

| Power (kw) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (kw) | 3 | |

| Complete machine | Track chassis model | LDZ60-4037 |

| Engine power (kw) | 400 | |

| Generator power (kw) | 400 | |

| Whole machine weight (t) | 60 | |

| Machine processing capacity (t/h) | 180-230 | |

| Total power of crushing work (kw) | 381.8 | |

| Working dimensions (length, width, height/mm) | 17652×7700×4000 | |

| Transportation dimensions (length, width, height/mm) | 17000×3500×4000 |

More Details

1. Single Power Version & Dual Power Version

SF-580D-S Mobile Integrated Crushing and Screening Machine is available in two versions: Single Power and Dual Power.

- Single Power Version: Requires an external power supply when crushing stones, suitable for job sites with stable electricity.

- Dual Power Version: More versatile. When a stable power supply is not available, the machine can operate directly with diesel.

2. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

3. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|