Working Principle

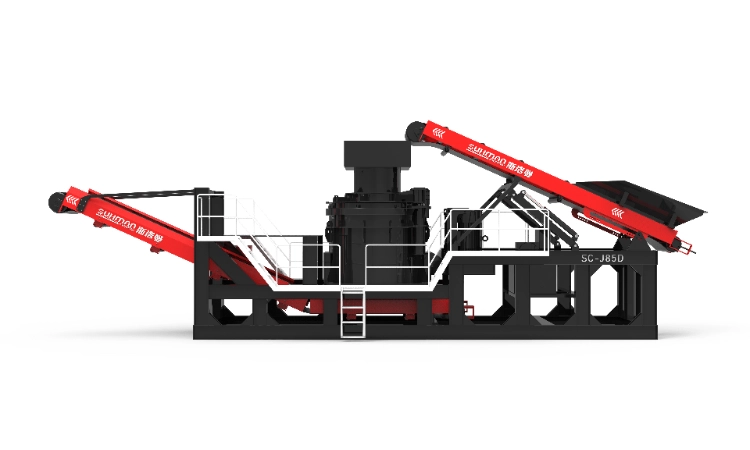

SC-J85D Modular VSI Sand Making Machine is a stationary vertical shaft impact (VSI) crusher designed with a modular structure, enabling flexible deployment in various sand production lines. At its core, it utilizes a high-speed rotor that throws incoming materials outward with strong centrifugal force. These materials collide either with the chamber lining or with other particles, generating powerful impact forces. This “rock-on-rock” or “rock-on-steel” crushing mechanism efficiently reduces particle size and improves aggregate shape.

Multiple feeding configurations are available—central feeding or combined central and ring feeding—allowing for adjustments based on material characteristics. The crushing chamber features replaceable liners, simplifying maintenance and reducing operational costs. SC-J85D Modular VSI Sand Making Machine also supports customizable rotor designs and distributor structures to match different raw materials and production requirements. Its modular, block-style layout makes it easy to transport, install, and expand, ensuring compatibility with various fixed production setups.

Application

SC-J85D Modular VSI Sand Making Machine is ideal for projects that demand high-quality sand with excellent particle shape and uniform grading. It plays a critical role in many fixed-site applications, including:

-

Manufactured Sand Production

Suitable for processing hard materials like river pebbles, basalt, limestone, and granite into high-quality manufactured sand for use in construction, roads, and hydraulic projects. -

Commercial Concrete and Dry-Mix Mortar Plants

Acts as a core sand-making module, providing consistent fine aggregates to ensure the stability of concrete and mortar mix quality. -

High-Grade Road Construction

Produces sand with optimized shape and grading for use in asphalt mixtures and stabilized base materials, enhancing road durability. -

Comprehensive Utilization of Mine Tailings

Converts low-value waste materials and tailings into usable sand, increasing resource efficiency and reducing environmental pressure.

With its compact footprint, SC-J85D Modular VSI Sand Making Machine is well-suited for deployment in space-constrained environments. Its modular architecture significantly shortens installation time and supports future capacity upgrades. It offers an efficient and scalable solution for stationary sand-making systems where reliability and adaptability are key.

Video Presentation

Product Parameter

| Serial number | Project | Description | SC-J85D |

| 1 | Feeding equipment | Hopper volume(m³) | 3 |

| 2 | Maximum feed size(mm) | 50 | |

| 3 | Feed capacity (t/h) | 100-300 | |

| 4 | Power of Feeder | 7.5(kw)×2 | |

| 5 | Impact Crusher For | Models | 85D |

| 6 | Maximum feed particle size (mm) | 50 | |

| 7 | Inlet size (length x width)(mm) | 1540×1000 | |

| 8 | Processing capacity(t/h) | 250 | |

| 9 | Power(kw) | 220 | |

| 10 | Weight(t) | 18 | |

| 11 | Main belt conveyor | Width/length (mm) | 1200×19100 |

| 12 | Discharge height(mm) | 3200 | |

| 13 | Power(kw) | 15 |

More Details

1. Single Power Version & Dual Power Version

SC-J85D Modular VSI Sand Making Machine is available in two versions: Single Power and Dual Power.

- Single Power Version: Requires an external power supply when crushing stones, suitable for job sites with stable electricity.

- Dual Power Version: More versatile. When a stable power supply is not available, the machine can operate directly with diesel.

2. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

3. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|