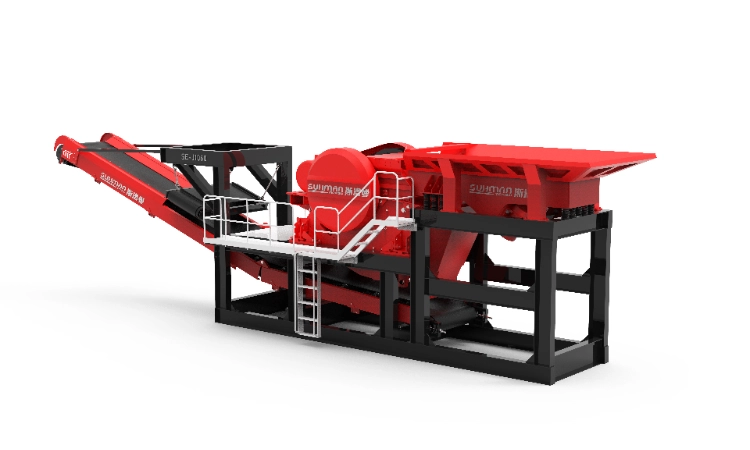

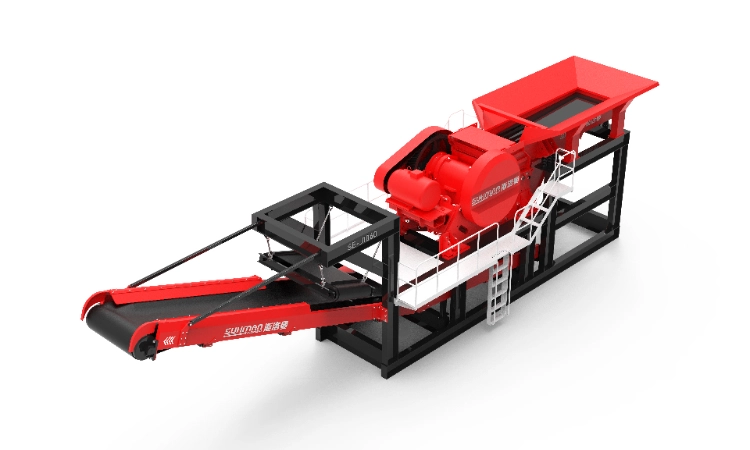

Working Principle

Suhman SE-J1060 modular jaw crusher operates using a mechanical compression method. A motor drives the belt and eccentric shaft, causing the movable jaw to move in a predetermined reciprocating motion. As material enters the crushing chamber, it is clamped and compressed between the fixed and moving jaws. With each stroke, the material is gradually reduced in size. Once sufficiently crushed, it descends under gravity and exits through the discharge opening.

The discharge size can be adjusted by modifying the wedge block setting, ensuring consistent and uniform output. Designed with a reinforced frame and wear-resistant components, the SE-J1060 is built for durability. Its modular construction allows for quick assembly, easy maintenance, and reliable performance under varying conditions.

Application

SE-J1060 modular jaw crusher is ideal for medium-scale crushing operations. It performs well in aggregate production, small and mid-sized mining projects, and road construction material recycling. Its design makes it particularly suitable for relocatable crushing lines such as temporary stone processing plants, mobile crushing zones in mining operations, or in-park material recovery stations.

Thanks to its modular nature, the SE-J1060 can be easily integrated with feeders, conveyors, and screening units to form a compact, custom crushing system. For job sites that demand quick deployment, space efficiency, and high mobility, the SE-J1060 offers a smart, high-performance solution.

Video Presentation

Product Parameter

| Serial number | Project | Description | SE-J1060 |

| 1 | Feeding equipment | Hopper volume(m³) | 5 |

| 2 | Feed height(mm) | 3800 | |

| 3 | Maximum feed size(mm) | 700 | |

| 4 | Size of feeder (length x width)(mm) | 3350×1000 | |

| 5 | Feed capacity (t/h) | 150-400 | |

| 6 | Power of Feeder | 3kw×2 | |

| 7 | Jaw Crusher | Models | 1060 |

| 8 | Maximum feed particle size (mm) | 700 | |

| 9 | Inlet size (length x width)(mm) | 750×1060 | |

| 10 | Processing capacity(t/h) | 200-250 | |

| 11 | Discharge particle size range(mm) | 0-300 | |

| 12 | Power(kw) | 110 | |

| 13 | Weight(t) | 14.35 | |

| 14 | Main belt conveyor | Width/length (mm) | 1200×22450 |

| 15 | Discharge height(mm) | 2950 | |

| 16 | Power(kw) | 15 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 |

More Details

1. Single Power Version & Dual Power Version

SE-J1060 Modular Jaw Crusher is available in two versions: Single Power and Dual Power.

- Single Power Version: Requires an external power supply when crushing stones, suitable for job sites with stable electricity.

- Dual Power Version: More versatile. When a stable power supply is not available, the machine can operate directly with diesel.

2. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

3. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|