Working Principle

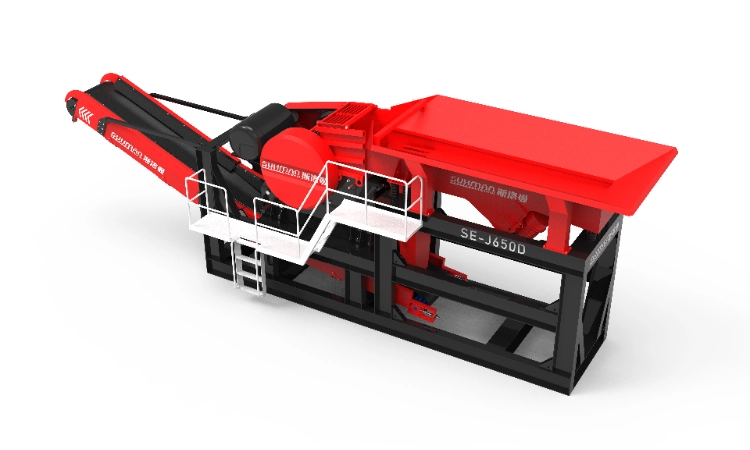

SE-J650D modular mini jaw crusher operates on a mechanical compression principle. Material enters the crushing chamber through the feed opening, where it is gripped and pressed between a fixed jaw plate and a moving jaw plate. Driven by an integrated motor and transmission system, the moving jaw follows a precise elliptical motion, applying repeated compressive forces to reduce the size of the input material.

As the material breaks down into smaller particles, SE-J650D gradually moves downward through the chamber until it reaches a size that allows it to pass through the adjustable discharge opening at the bottom. This controlled crushing process ensures consistent output size and minimizes over-crushing, making the SE-J650D both efficient and reliable for light-duty crushing operations.

Application

SE-J650D is ideally suited for lightweight crushing tasks such as jobsite processing, small-scale aggregate production, and handling leftover materials in mining operations. Its compact structure and ease of maintenance make it especially practical for sites with space limitations, minimal foundation preparation, or urgent deployment requirements—such as rural building demolition, school renovations, and pipeline excavation backfilling.

In addition, thanks to its modular design, SE-J650D can be flexibly paired with various conveying or screening units to form a compact integrated crushing system, offering scalable solutions for diverse operational needs.

Video Presentation

Product Parameter

| Serial number | Project | Description | SE-J650D |

| 1 | Feeding equipment | Hopper volume(m³) | 4 |

| 2 | Feed height(mm) | 3500 | |

| 3 | Maximum feed size(mm) | 500 | |

| 4 | Size of feeder (length x width)(mm) | 3600×700 | |

| 5 | Feed capacity (t/h) | 50-130 | |

| 6 | Power of Feeder | 3kw×2 | |

| 7 | Jaw Crusher | Models | 57 |

| 8 | Maximum feed particle size (mm) | 500 | |

| 9 | Inlet size (length x width)(mm) | 500×700 | |

| 10 | Processing capacity(t/h) | 50-130 | |

| 11 | Discharge particle size range(mm) | 0-100 | |

| 12 | Power(kw) | 75 | |

| 13 | Weight(t) | 10.1 | |

| 14 | Main belt conveyor | Width/length (mm) | 800×15100 |

| 15 | Discharge height(mm) | 2100 | |

| 16 | Power(kw) | 11 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 |

More Details

1. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

2. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|