Working Principle

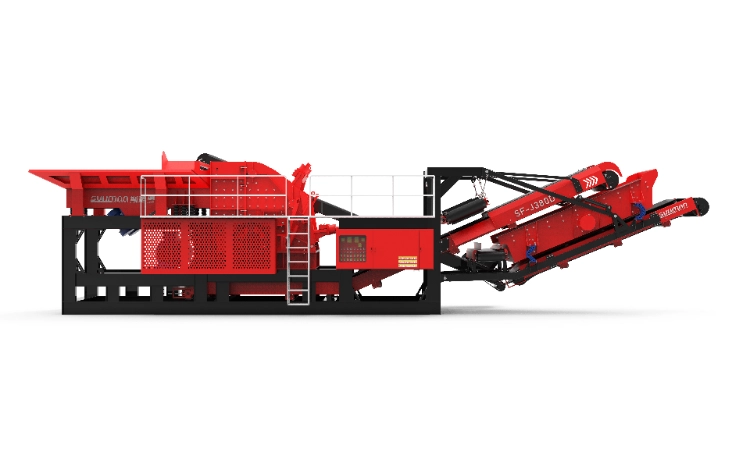

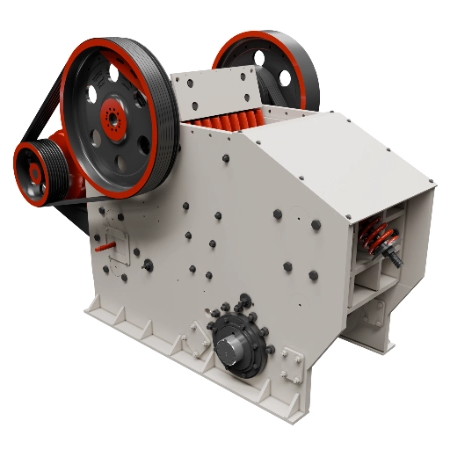

SF-J380D Modular Impact Crusher is a stationary impact crusher designed with a modular structure, engineered to efficiently process materials such as concrete, asphalt, and construction waste. At the core of its operation is a high-inertia rotor and a mechanical clamping impact plate system. As the rotor spins at high speed, it propels the incoming material against the impact plates, causing it to fracture under intense kinetic energy. This method ensures high crushing efficiency while reducing wear on key components.

The crusher features adjustable settings, allowing operators to control the final product size by modifying the rotor speed or the spacing between the impact plates and the crushing chamber. This makes the SF-J380D adaptable to various material specifications and output requirements.

Application

SF-J380D Modular Impact Crusher offers wide-ranging versatility and is ideal for a variety of applications involving medium-hard to hard materials:

-

Construction Waste Recycling

Capable of processing demolished concrete, asphalt pavement, and bricks, turning waste into reusable aggregate. -

Asphalt and Concrete Reprocessing

Suitable for re-crushing road surfaces and old concrete structures to produce qualified recycled materials. -

Stone Crushing and Quarry Operations

Effective in processing limestone, sandstone, quartz, slag, and other mineral aggregates in quarry and mining sites. -

Compact Crushing Solutions for Industrial Sites

Its modular design allows for quick integration into existing production lines, making it a reliable choice for small to mid-sized processing plants and recycling facilities.

SF-J380D Modular Impact Crusher is compact yet powerful, with a maximum feed size of up to 700 mm and a processing capacity of 150 to 350 tons per hour. It comes equipped with a vibrating feeder and screening unit, enabling fast deployment and efficient onsite crushing operations.

Video Presentation

Product Parameter

| Serial number | Project | Description | SF-J380D |

| 1 | Feeding equipment | Hopper volume(m³) | 5 |

| 2 | Feed height(mm) | 3700 | |

| 3 | Maximum feed size(mm) | 700 | |

| 4 | Size of feeder (length x width)(mm) | 3500×1300 | |

| 5 | Feed capacity (t/h) | 150-350 | |

| 6 | Power of Feeder | 3(kw)×2 | |

| 7 | Impact Crusher | Models | 380D |

| 8 | Maximum feed particle size (mm) | <700 | |

| 9 | Inlet size (length x width)(mm) | 1380×1000 | |

| 10 | Processing capacity(t/h) | 150-180 | |

| 11 | Power(kw) | 250 | |

| 12 | Weight(t) | 16 | |

| 13 | Vibrating screen | Screen size (length x width)(mm) | 5000×1500 |

| 14 | Maximum feeding granularity(mm) | 100 | |

| 15 | Processing capacity(t/h) | 150-450 | |

| 16 | Power(kw) | 3.7(kw)×2 | |

| 17 | The number of screen layer (layer) | 1 | |

| 18 | Sift down the belt | Width/length (mm) | 1000×11500 |

| 19 | Discharge height(mm) | 2600 | |

| 20 | Power(kw) | 7.5 | |

| 21 | Main belt conveyor (top of the screen) | Width/length (mm) | 1200×22050 |

| 22 | Discharge height(mm) | 3400 | |

| 23 | Power(kw) | 15 | |

| 24 | Iron remover | Models | RCYD-12 |

| 25 | Power(kw) | 3 | |

| 26 | Processing capacity(t/h) | 0-20 | |

| 27 | Size(mm) | 2100*1450*420 | |

| 28 | Weight(kg) | 900 | |

| 29 | Side belt conveyor | Width/length (mm) | / |

| 30 | Discharge height(mm) | / | |

| 31 | Power(kw) | / | |

| 32 | Transition Belt Machine | Width/length (mm) | 500×4400 |

| 33 | Discharge height(mm) | 1300 | |

| 34 | Power(kw) | 3 | |

| 35 | Return material belt machine | Width/length (mm) | 500×15700 |

| 36 | Discharge height(mm) | 4000 | |

| 37 | Power(kw) | 5.5 |

More Details

1. Single Power Version & Dual Power Version

SF-J380D Modular Impact Crusher is available in two versions: Single Power and Dual Power.

- Single Power Version: Requires an external power supply when crushing stones, suitable for job sites with stable electricity.

- Dual Power Version: More versatile. When a stable power supply is not available, the machine can operate directly with diesel.

2. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

3. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|