Working Principle

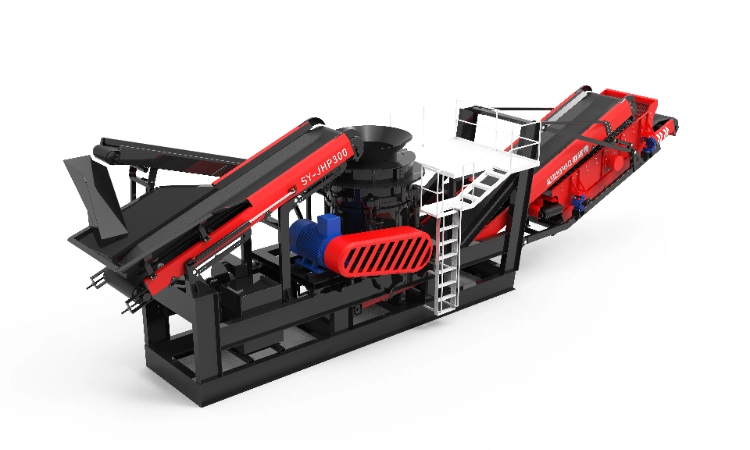

SY‑JHP300 is designed as a stationary, modular cone crusher for efficient secondary and tertiary crushing. It employs a multi-cylinder hydraulic system that drives a mechanically balanced, gyrating inner cone within a fixed outer cone. This motion compresses material in a laminated crushing process—where rocks are crushed between the moving mantle and stationary bowl liner under high pressure—delivering uniform particle shapes and excellent reduction ratios.

Hydraulic adjustments allow precise control over the discharge opening to tailor end-product size, while integrated overload protection safeguards the crusher if uncrushable material enters, automatically releasing hydraulic pressure before re-engaging. Its modular design consists of interchangeable core components and a plug-and-play foundation, enabling fast installation and straightforward maintenance.

Application

- Aggregate production: Ideal for crushing granite, basalt, and other hard stones to produce high-quality aggregates with cubical shapes for use in concrete and asphalt.

- Mining operations: Suitable for non-metallic and metallic ores in secondary or tertiary stages, especially when integrated into larger crushing circuits.

- Stationary crushing plants: Modular design allows quick installation in fixed plant layouts, offering scalability and flexibility for ramping up production.

Video Presentation

Product Parameter

| Serial number | Project | Description | SY-JHP300 |

| 1 | Feeding equipment | Hopper volume(m³) | 2 |

| 2 | Feed height(mm) | 2800 | |

| 3 | Maximum feed size(mm) | 210 | |

| 4 | Size of feeder (length x width)(mm) | 10250×1000 | |

| 5 | Feed capacity (t/h) | 150-300 | |

| 6 | Power of Feeder | 7.5 | |

| 7 | Cone Crusher | Models | HP300 |

| 8 | Maximum feed particle size (mm) | 210 | |

| 9 | Size range of ore discharge outlet (mm) | 0-51 | |

| 10 | Processing capacity(t/h) | 200-300 | |

| 11 | Power(kw) | 250 | |

| 12 | Weight(t) | 18.7 | |

| 13 | Vibrating screen | Screen size (length x width)(mm) | 5000×1500 |

| 14 | Maximum feeding granularity(mm) | 100 | |

| 15 | Processing capacity(t/h) | 150-500 | |

| 16 | Power(kw) | 3.7kw×2 | |

| 17 | The number of screen layer (layer) | 1 | |

| 18 | Main belt conveyor (top of the screen) | Width/length (mm) | 1200×21250 |

| 19 | Discharge height(mm) | 3400 | |

| 20 | Power(kw) | 15 | |

| 21 | Sift down the belt | Width/length (mm) | 1000×11500 |

| 22 | Discharge height(mm) | 2500 | |

| 23 | Power(kw) | 7.5 | |

| 24 | Transition Belt Machine | Width/length (mm) | 500*4400 |

| 25 | Discharge height(mm) | 1400 | |

| 26 | Power(kw) | 3 | |

| 27 | Return material belt machine | Width/length (mm) | 500*19850 |

| 28 | Discharge height(mm) | 3950 | |

| 29 | Power(kw) | 5.5 |

More Details

1. Single Power Version & Dual Power Version

SY-JHP300 Modular Cone Crusher is available in two versions: Single Power and Dual Power.

- Single Power Version: Requires an external power supply when crushing stones, suitable for job sites with stable electricity.

- Dual Power Version: More versatile. When a stable power supply is not available, the machine can operate directly with diesel.

2. Engine

- Standard Configuration: Equipped with a branded engine meeting China National III emission standard.

- Optional Upgrades: Can be upgraded to China Stage IV, EPA Tier 4, or Euro V engines to comply with local environmental regulations.

3. Delivery Terms

| Item | Terms |

|---|---|

| Delivery Time | Approx. 20–25 working days after down payment |

| Warranty | 12 months |

| Spare Parts | A full set of wear parts will be provided with the machine, and long-term supply is guaranteed |

| Service & Support |

|